In recent years, inventory management has become more streamlined, and as a result more efficient due to new techniques and technologies. However, 43% of small businesses surveyed still do not track inventory or use a manual system, leaving the organization susceptible to errors and unhappy customers.¹ Investing in an inventory management system and staying abreast of trends can help your business avoid common pitfalls of those without effective inventory management systems.

Whether its an eCommerce business, a brick-and-mortar store, or a combination of the two, inventory management is critical to avoid overselling and under delivering. With the new year now upon us, we wanted to share some inventory management techniques to help your business hit the ground running in 2019.

Tracking key performance indicators (KPIs), conducting ABC analysis, setting par levels, and centralizing your inventory management system are just four inventory management techniques to leverage moving forward.

Track Key Performance Indicators (KPIs) for Inventory

Key performance indicators (KPIs) are essential metrics in any vertical as they serve as the basis for achievement. In inventory management, there are three main groups of KPIs: sales, receiving, and operational.

Sales KPIs include: stock-to-sales ratio, sell-through rate, weeks-on-hand, inventory turnover rate, backorder rate, and days-to-sell inventory. Receiving KPIs include: time-to-receive and put- away time. Operational KPIs include: on-time orders, shrinkage, average inventory, rate of returns, cost of carrying inventory.

While some may believe sales KPIs are most important, when it comes to inventory management, operational KPIs are the most essential. Three of the more unique operational KPIs to know are:

- Shrinkage which refers to the percentage of inventory listed in records but is not in the actual inventory. This can be problematic when it comes to order fulfillment. A customer may place an order thinking the item is in stock, only to find out there was a data inaccuracy.

- Average inventory which is a metric that is used as a guide to determine average stock levels to ensure order fulfillment and stock on hand.

- Cost of carrying inventory which is a percentage of spend on inventory overhead – holding and storing inventory – each year.

Conduct ABC Analysis

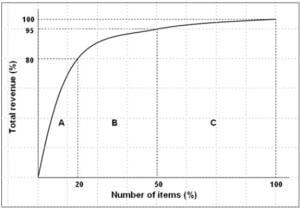

Businesses will deliver three tiers of goods: A, B, and C. The ABC analysis is based off the Pareto principle which states that 80% of the output comes from 20% of the input. An ABC analysis helps organizations determine consumption value of goods and services. Items in tier A are scarcely purchased but have very high value. Tier C items are purchased frequently, and as a result have the lowest value. Tier B items fall between tier A and C.

We have also included an example of an ABC analysis² to visualize this model.

Using this method of categorization of products can help an organization prioritize inventory needs and determine which products deliver the most value. For example, tier C items need to be plentiful as they fly off the shelves. Organizations can afford to have fewer tier A items available as they are purchased less.

Set Par Levels

Determining a baseline for inventory counts can help simplify the inventory management process. For instance, your store has 50 pairs of shoes in stock, but requires a minimum of 25 pairs to always be available. Once the 26th pair is sold, key reports will highlight the need to place an order with your vendor to make sure you always have the desired amount available, guaranteeing stock and order fulfillment.

Centralize Your Inventory Management System

Too often, an organization will have separate systems for inventory between the warehouse, eCommerce site, and brick-and-mortar store location. The inconsistency can lead to orders being left unfulfilled, and ultimately unhappy customers. Once you have a centralized system in place, be sure to periodically conduct a physical inventory to make sure inventory counts are accurate.

Using an inventory management system, like the one Runit provides, helps organize inventory in real-time across store locations to ensure high accuracy and eliminate the need for manual tracking, a tedious and error-prone process. Following these inventory management techniques will set your business up for success in the years to come.

Runit offers a cloud-based POS and inventory management system designed for multi-store apparel, footwear, sports, and gift merchants to streamline their operations and guarantee order fulfillment for greater customer satisfaction.

¹http://www.waspbarcode.com/small-business-report

²https://industrialengg.files.wordpress.com/2011/06/abc-analysis1.jpg?w=300&h=154